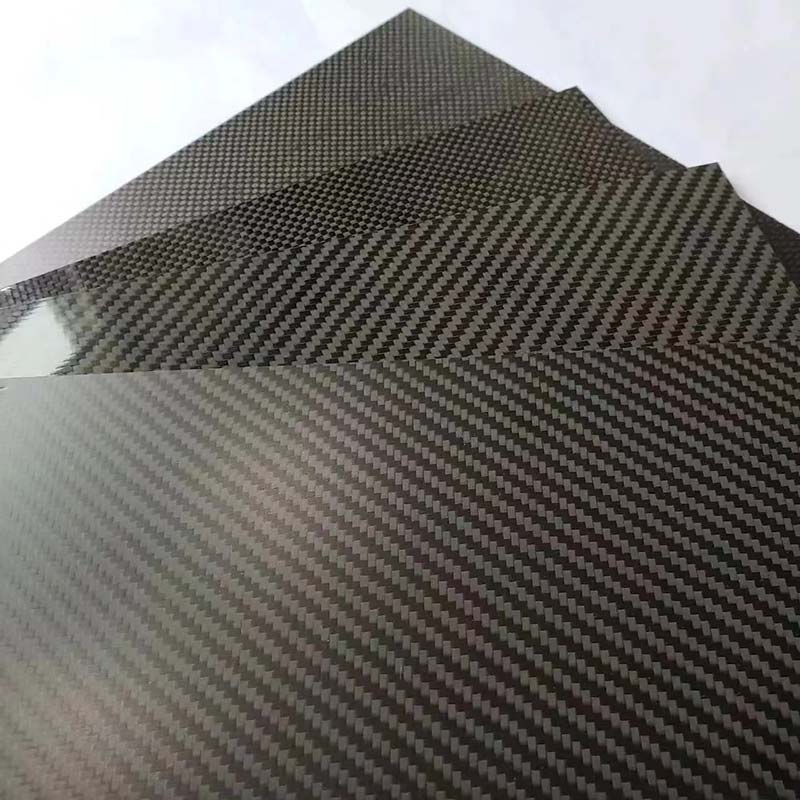

Custom Carbon Fiber Panel Sheet

Please click the button below to contact us.

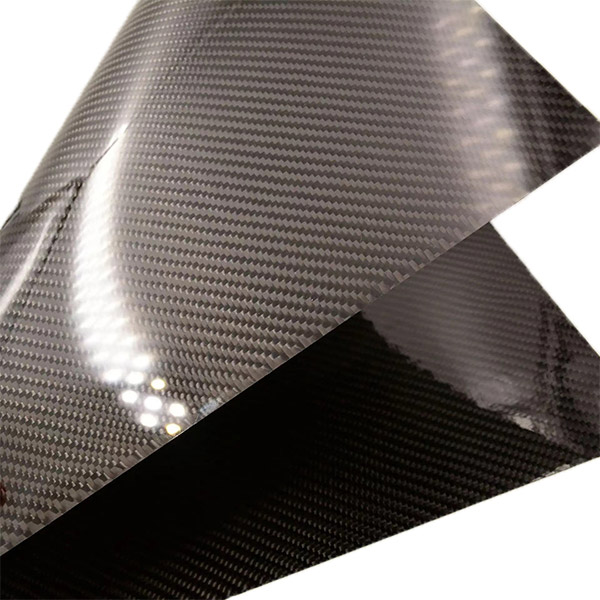

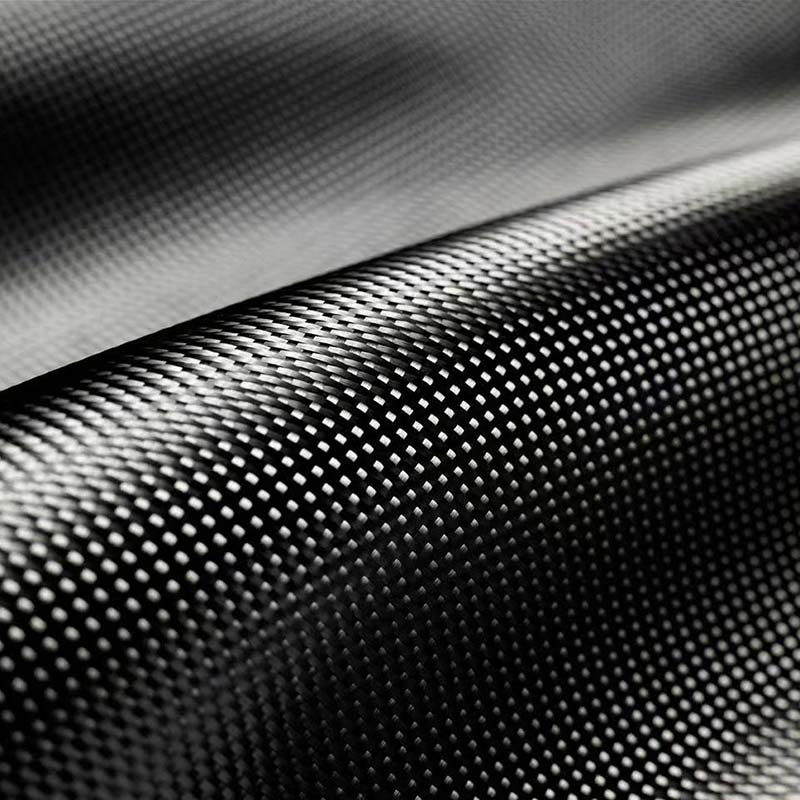

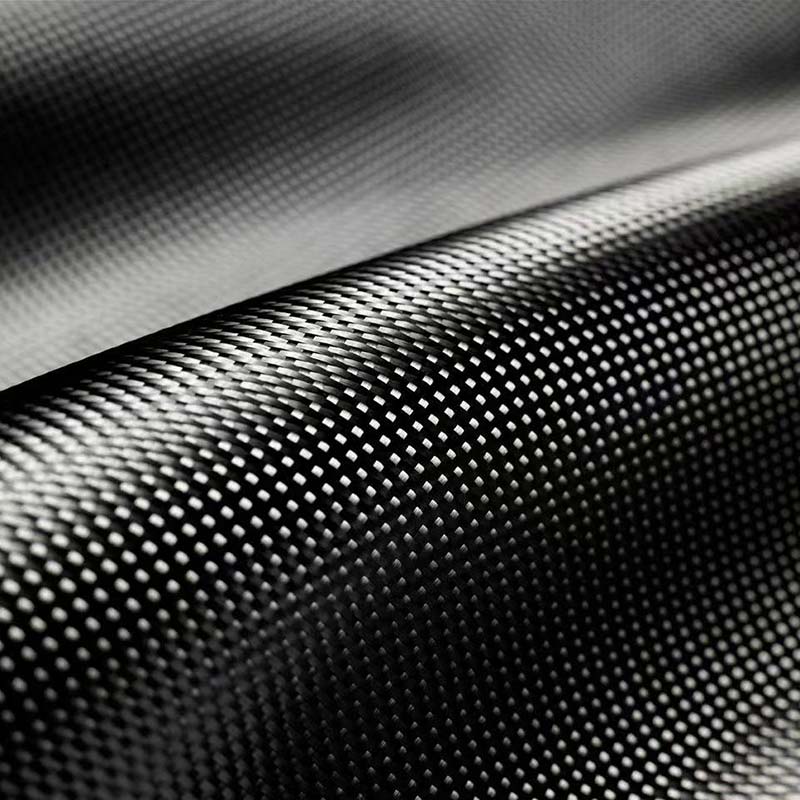

Introduction:Carbon Fiber Panel Sheet is a high-performance sheet material that uses carbon fiber as a reinforcement material and is usually compounded with matrix materials such as resin. Carbon fiber is a high-strength, high-modulus fiber with a carbon content of more than 95%, and has a unique microstructure and excellent physical and chemical properties.

Product Description

carbon fiber panel sheet is a high-performance sheet material that uses carbon fiber as a reinforcement material and is usually compounded with matrix materials such as resin. Carbon fiber is a high-strength, high-modulus fiber with a carbon content of more than 95%, and has a unique microstructure and excellent physical and chemical properties. After high-temperature carbonization and other processes, its raw fibers are formed into fibers with a graphite microcrystalline structure. These fibers are interwoven and arranged. After being compounded with matrix materials such as resin, they can give full play to the high strength and high modulus of carbon fiber, thereby giving carbon fiber panels excellent comprehensive performance, making it have a wide range of application prospects in many fields, and is one of the indispensable high-performance materials in modern industry.

carbon fiber panel sheet Features:

1. Excellent lightweight strength

Custom Carbon Fiber Panel Sheet achieves ultra-light weight while ensuring high strength. Its density is only 1.75 - 1.85g/cm³, which is much lower than traditional metal materials, such as steel, which has a density of about 7.85g/cm³. Under the same load-bearing conditions, the use of carbon fiber panels can significantly reduce the weight of the structure. For example, in the aerospace field, replacing traditional metal parts with carbon fiber panels can reduce the weight of aircraft by 20% - 30%, thereby improving fuel efficiency and increasing range. This light-weight and strong characteristic makes carbon fiber panels have significant advantages in the pursuit of high-performance and lightweight designs, and can meet the needs of various weight-sensitive application scenarios.

2. Excellent rigidity

Carbon Fiber Panel Sheet has an elastic modulus of up to 230 - 250GPa and has excellent rigidity. This means that when subjected to external forces, the product can maintain good shape and dimensional stability and is not easily deformed. Compared with aluminum alloy, its elastic modulus is 3-5 times that of aluminum alloy. When manufacturing high-precision mechanical parts or structural parts, such as the spindle parts of high-end machine tools and the shells of precision instruments, carbon fiber panels can ensure that the parts maintain precise positioning and running accuracy during long-term use, reduce the errors caused by material deformation, thereby improving the overall performance and reliability of the equipment, and meeting the application requirements of high-end manufacturing industry for material rigidity.

3. Corrosion resistance

Custom Carbon Fiber Panel Sheet has excellent corrosion resistance and can resist erosion by a variety of chemical media. It shows good stability in chemical environments such as acid, alkali, and salt. For example, its performance hardly changes significantly after long-term immersion in 10% hydrochloric acid solution or 20% sodium hydroxide solution. This makes carbon fiber panels widely used in chemical industry, marine engineering and other fields. In chemical equipment, such as pipelines, storage tanks and other parts, the use of carbon fiber panels can effectively prevent chemical media from corroding materials and extend the service life of the equipment; in the marine environment, ship parts and offshore platform structures made of carbon fiber panels can resist the erosion of seawater, reduce maintenance costs, and provide a reliable material choice for engineering applications in harsh chemical environments.

4. Versatility

Carbon Fiber Panel Sheet not only has excellent mechanical properties, but also has a variety of functional characteristics. It has good electrical conductivity, with a resistivity as low as 10⁻⁴Ω·cm. It can be used in the field of electromagnetic shielding, such as the housing and shielding cover of electronic equipment, effectively preventing electromagnetic interference and ensuring the normal operation of the equipment. At the same time, carbon fiber panels also have a certain thermal conductivity, with a thermal conductivity of 200-300W/(m·K), which can be used to manufacture heat dissipation components, such as heat sinks for high-performance computers, heat dissipation housings for electronic components, etc., to improve the heat dissipation efficiency of the equipment and ensure the stability of the equipment when running under high load. In addition, carbon fiber panels can also achieve other specific functions, such as fire prevention, flame retardancy, anti-static, etc. through special surface treatment or composite processes, to meet the diverse functional requirements in different application scenarios, showing strong versatility and providing broad space for product innovation design and application expansion.

Carbon Fiber Panel Sheet Application:

1. Aerospace field

In the aerospace field, Custom Carbon Fiber Panel Sheet can be used to manufacture aircraft wings, fuselage structural parts, etc. Its light weight and high strength characteristics can effectively reduce the weight of aircraft, reduce fuel consumption, and improve flight efficiency. For example, the wings of a new commercial aircraft use carbon fiber panels as the main structural material. Compared with traditional aluminum alloy wings, the weight is reduced by about 25%, while the strength and rigidity are guaranteed, which increases the aircraft's range by 15%. In addition, the corrosion resistance of carbon fiber panels also enables it to adapt to the complex climatic conditions in the aerospace environment, reduce maintenance costs, improve the safety and reliability of aircraft, and provide important material support for the development of the aerospace industry.

2. Automobile manufacturing industry

Custom Carbon Fiber Panel Sheet can be used in automobile manufacturing to produce automobile body parts, engine hoods, roofs, etc. Automobile parts made of carbon fiber panels can not only reduce the weight of the car, improve fuel economy, but also enhance the safety of the car. For example, a high-end sports car uses a large amount of carbon fiber panels in its body, which reduces the weight of the whole vehicle by 30% and shortens the acceleration time from 0 to 100 kilometers by 0.5 seconds. At the same time, in the collision test, the carbon fiber panels can effectively absorb and disperse the impact energy to protect the safety of the people in the car. With the pursuit of lightweight and high performance in the automotive industry, the application of carbon fiber panels will become more and more extensive, promoting the development of the automotive manufacturing industry in a more energy-saving, environmentally friendly, safe and efficient direction.

3. High-end sports equipment

Custom Carbon Fiber Panel Sheet is an ideal material for manufacturing high-end sports equipment, such as bicycle frames, fishing rods, golf clubs, etc. Taking bicycle frames as an example, the frames made of carbon fiber panels are light in weight and high in strength, which can provide better handling performance and comfort for riders. Compared with traditional metal frames, the weight of carbon fiber frames can be reduced by 40% - 50%, and at the same time, they have good anti-fatigue performance and can withstand the test of long-term riding. In the application of fishing rods and golf clubs, the high rigidity and light weight of carbon fiber panels can improve the performance of sports equipment, making fishing rods more sensitive and golf clubs more effective, providing athletes and enthusiasts with a better sports experience and promoting the development of the sports equipment industry towards high performance and specialization.

4. Electronic equipment manufacturing

In the field of electronic equipment manufacturing, carbon fiber panels can be used to produce housings and heat dissipation components of electronic products. Its good electrical conductivity and thermal conductivity enable it to meet the needs of electronic equipment for electromagnetic shielding and heat dissipation. For example, in the heat dissipation system of high-performance computers, heat sinks made of carbon fiber panels can quickly conduct the heat generated by the chip to ensure the stability of the computer when running under high load. At the same time, the light weight of carbon fiber panels also helps to reduce the overall weight of electronic equipment and make it more portable. In addition, carbon fiber panels can also be used to manufacture the housing of electronic equipment, providing good protection performance, preventing external impact from damaging the internal components of the equipment, improving the reliability and service life of electronic equipment, and providing a strong material guarantee for the miniaturization and high performance development of electronic equipment.

5. Medical equipment field

Custom Carbon Fiber Panel Sheet also has important applications in the field of medical equipment, such as manufacturing surgical instruments and medical equipment housings. Its good biocompatibility and corrosion resistance enable it to meet the strict requirements of medical devices used in the human body and in the medical environment. For example, surgical instruments made of carbon fiber sheets will not cause adverse reactions in the human body when used in the human body, while maintaining good strength and rigidity to ensure the smooth progress of the operation. In the application of medical device shells, carbon fiber sheets can provide good protection to prevent external factors from interfering with and damaging the precision components inside the equipment. At the same time, its lightweight characteristics also help to reduce the weight of medical devices, facilitate the operation and use of medical staff, and provide important material support for the high performance and high reliability development of medical devices.

6.Building decoration industry

In the field of building decoration, Custom Carbon Fiber Panel Sheet can be used to manufacture building decorative panels, structural reinforcement components, etc. Decorative panels made of carbon fiber sheets have a unique appearance and texture, which can add a sense of modernity and technology to the building. At the same time, the high strength and high modulus characteristics of carbon fiber sheets enable it to be used as a structural reinforcement material to reinforce the beams, columns and other structures of buildings, and improve the seismic resistance and bearing capacity of buildings. For example, in the reinforcement and renovation project of an old building, carbon fiber panels were used to reinforce the beams and columns of the building. After testing, the load-bearing capacity of the reinforced structure increased by 30%, and the seismic performance was significantly improved. The application of carbon fiber panels in building decoration and structural reinforcement can not only improve the aesthetics of the building, but also improve the safety and service life of the building, providing new ideas and material choices for the sustainable development of the construction industry.

Carbon Fiber Panel Sheet FAQs:

What are the primary benefits of carbon fiber panel sheets compared to other materials?

Carbon fiber panel sheets offer exceptional strength-to-weight ratio, corrosion resistance, durability, and high stiffness, making them ideal for applications requiring lightweight yet robust material solutions.

Can you customize carbon fiber panel sheets according to our specific requirements?

Yes, we offer customization services to tailor carbon fiber panel sheets to your exact specifications, including dimensions, surface finishes, and resin systems, ensuring optimal performance for your application.

How do you ensure the consistency of carbon fiber panel sheet production?

We implement rigorous quality control measures throughout the manufacturing process, including raw material inspection, precise machining, and thorough testing, to maintain the highest standards of consistency and reliability in our products.

What industries commonly use carbon fiber panel sheets?

Our carbon fiber panel sheets are utilized across various industries, including aerospace, automotive, marine, defense, sports and recreation, industrial equipment, and architectural applications, due to their exceptional performance and versatility.

Can you provide technical assistance and support during the design and implementation phases?

Yes, our team of experienced engineers and technical experts is available to offer comprehensive support and guidance at every stage of your project, from initial design consultation to post-installation assistance, ensuring optimal results and customer satisfaction.

How do carbon fiber panel sheets perform in extreme temperature environments?

Carbon fiber panel sheets exhibit excellent thermal stability and resistance to temperature extremes, maintaining their structural integrity and mechanical properties over a wide range of operating temperatures, from sub-zero to high heat conditions.

What are the recommended methods for cutting and machining carbon fiber panel sheets?

We recommend using specialized cutting tools and machining techniques designed for composite materials to achieve clean and precise cuts without compromising the integrity of the carbon fiber panel sheets. Our technical team can provide guidance on the most suitable methods for your specific application.

Are there any special handling or storage requirements for carbon fiber panel sheets?

Carbon fiber panel sheets should be stored in a clean, dry environment away from direct sunlight and moisture to prevent any degradation or damage to the material. Additionally, proper handling procedures should be followed to avoid excessive bending or impact during transportation and installation.