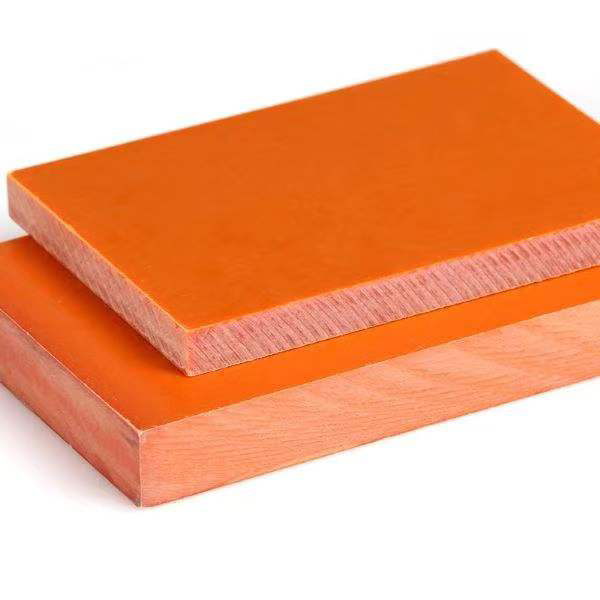

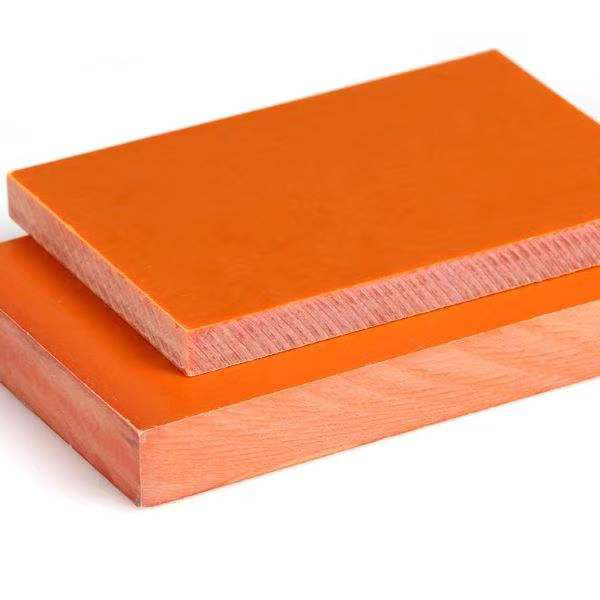

Electrical Insulation Epoxy Resin Fiberglass

Please click the button below to contact us.

Introduction:Electrical Insulation Epoxy Resin Fiberglass is a composite material with epoxy resin as the matrix and glass fiber as the reinforcement material.

Product Description

Electrical Insulation Epoxy Resin Fiberglass is a composite material with epoxy resin as the matrix and glass fiber as the reinforcement material. It combines glass fiber with epoxy resin to form a material with excellent electrical insulation performance, mechanical strength and chemical corrosion resistance. It is widely used in power, electronics, aerospace and other fields.

Electrical Insulation Epoxy Resin Fiberglass Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Product Features

Excellent electrical insulation performance

High insulation resistance and dielectric strength, suitable for high-voltage electrical equipment.

Low dielectric constant and dielectric loss factor, reducing signal transmission loss.

Excellent mechanical properties

High tensile strength and bending strength, strong ability to withstand mechanical stress.

Good impact resistance, not easy to crack, extending the service life of the equipment.

Strong chemical corrosion resistance

Resistant to chemicals such as acids, alkalis, salts, suitable for harsh environments.

Outstanding hydrolysis resistance and moisture resistance, adaptable to high temperature and high humidity environments.

Stable heat resistance

High thermal deformation temperature (usually over 130°C), meeting the needs of long-term high temperature use.

Low thermal expansion coefficient, good matching with metal materials, reducing thermal stress.

Good processing performance

Can be formed by molding, lamination, winding and other processes to meet the needs of complex shapes.

The surface can be painted, printed and other secondary processes to improve aesthetics.

Environmentally friendly and safe

Does not contain harmful substances such as asbestos, meeting environmental standards.

Low smoke and halogen-free, reducing the release of toxic gases during fire.

Technical process

Material preparation

Mix epoxy resin and curing agent in proportion, add glass fiber cloth or felt, and form prepreg through hot pressing or impregnation process.

Molding process

Compression molding: put the prepreg into the mold, heat and pressurize to cure and mold, suitable for manufacturing complex shaped products.

Lamination molding: stack multiple layers of prepreg, cure through a hot press, and produce plates or pipes.

Filming molding: impregnate continuous glass fiber with resin and wind it on a rotating core mold, suitable for manufacturing rotating bodies such as pipelines and tanks.

Post-processing

After curing, cutting, drilling, grinding and other mechanical processing are carried out to meet the requirements of dimensional accuracy.

The surface is coated with moisture-proof and anti-corrosion coating to improve the protection performance.

Application field

Power industry

Transformer and reactor: as insulating structural parts, improve the insulation level of equipment and reduce the risk of short circuit.

High-voltage switchgear: manufacture insulating partitions, contact boxes, etc. to ensure the safe operation of equipment.

Cable terminals and connectors: provide insulation support to prevent breakdown caused by electric field concentration.

Electronics Industry

Printed Circuit Board (PCB): As a substrate material, it provides electrical insulation and mechanical support to improve signal transmission stability.

Electronic Packaging: Used for chip packaging to protect electronic components from the external environment.

Connectors and Sockets: Manufacture insulating shells to prevent leakage and short circuits.

Aerospace

Aircraft structural parts: Manufacture radomes, antenna covers, etc. to reduce weight while ensuring strength.

Satellite components: Used for solar panel brackets, antenna structures, etc. to adapt to the extreme environment of space.

Rocket engines: Manufacture combustion chambers, nozzles and other components to withstand high temperatures and high pressures.

Transportation

Automotive electronics: Manufacture sensor housings, battery pack insulation layers, etc. to improve safety and reliability.

Rail transit: Used for traction transformers, inverters, etc. to adapt to high-speed operation requirements.

Marine electrical: Manufacture distribution boards, cable troughs, etc. to adapt to humid salt spray environments.

New energy field

Wind power generation: Manufacture blades and tower insulation parts to improve equipment weather resistance.

Photovoltaic power generation: Used for photovoltaic inverters, junction boxes, etc. to adapt to long-term outdoor use.

Energy storage system: manufacture battery module shell, insulating partition, etc. to ensure system safety.

Industrial equipment

Motors and generators: manufacture insulating end caps, stator cores, etc. to improve equipment efficiency.

High-voltage switches: manufacture insulating pull rods, operating mechanisms, etc. to ensure safe operation.

Transformers: manufacture core clamps, oil tanks, etc. to extend equipment life.

Maintenance and cleaning

Maintenance recommendations

Regular inspection: observe whether the surface has cracks, deformation or reduced insulation performance.

Moisture-proof measures: avoid long-term exposure to humid environments, and use desiccant when necessary.

Mechanical damage prevention: avoid contact with sharp objects to prevent scratches or punctures.

Cleaning method

Surface cleaning: wipe with a soft cloth or lint-free cloth, avoid using a hard brush.

Cleaner selection: use a neutral detergent (such as soapy water) and avoid strong acids and alkalis.

Stubborn stains: can be treated with alcohol or special detergents, but avoid soaking the inside of the material.

FAQs

Q: Is the material resistant to high temperatures?

A: The temperature resistance range is usually -50℃ to 130℃ (can withstand higher temperatures in a short period of time), which depends on the resin formula.

Q: Is it recyclable?

A: It can be recycled, but professional equipment is required to separate the resin and glass fiber.

Q: Is special equipment required during processing?

A: Professional equipment such as high-temperature presses, laminators or winding machines are required to ensure that the resin is fully cured.

Q: Is it FDA-certified?

A: Some formulas can pass, and compliant resins need to be selected according to specific applications (such as food contact).

Q: Is the material flame retardant?

A: UL94 V-0 rating can be achieved by adding flame retardants to meet fire protection requirements.

Q: How long is the service life?

A: It can reach more than 20 years under normal conditions, depending on the application scenario and maintenance.

Q: Is the color customized?

A: Pigments can be added to achieve customized colors, but attention should be paid to the impact on electrical performance.

Q: Is the material environmentally friendly?

A: It complies with RoHS and REACH standards and does not contain heavy metals and hazardous substances.