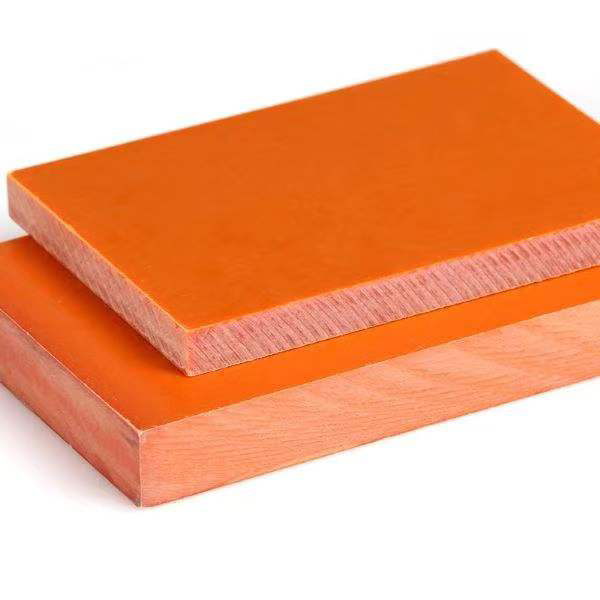

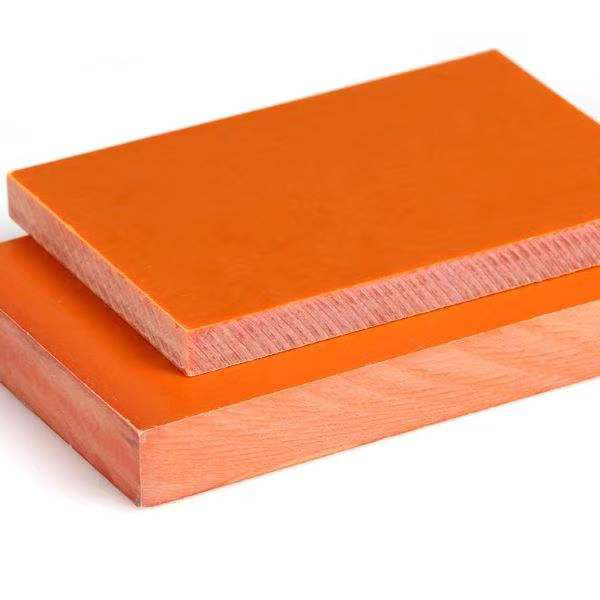

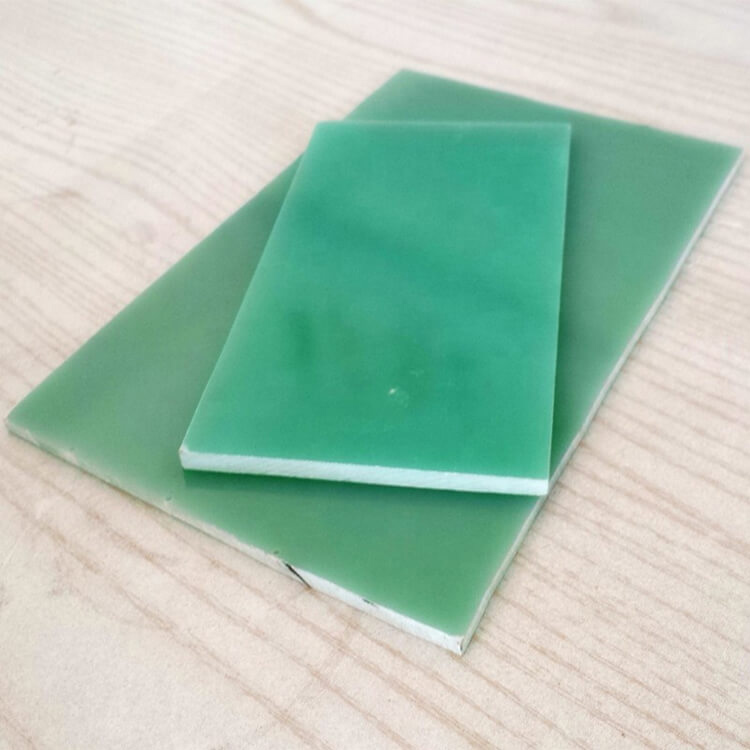

FR4 Fiberglass Sheet

Please click the button below to contact us.

Introduction:Fr4 Fiberglass Sheet is a composite material with glass fiber cloth as reinforcement material and epoxy resin as matrix. It meets the UL94 V-0 flame retardant standard and has excellent electrical insulation, mechanical strength and heat resistance.

Product Description

FR4 Fiberglass Sheet is a high-performance engineering material primarily composed of a composite of glass fiber and epoxy resin. It is widely used in the electronics, electrical, and mechanical fields, and is highly sought after for its excellent physical and chemical properties. Its high density, low water absorption, and high strength meet the stringent requirements of a wide range of industrial applications. Its stable chemical properties ensure excellent performance in a wide range of environments, including high temperatures, humidity, and high mechanical stress.

FR4 Fiberglass Sheet Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

FR4 Fiberglass Sheet Features:

1. High Density:

FR4 Fiberglass Sheet has a density of 1.8–2.0 g/cm³, which gives it excellent mechanical properties and stability. In electronic devices, this high density effectively prevents component loosening and displacement, ensuring long-term stable operation. This high density also means the material is highly durable, capable of maintaining its structural integrity in harsh environments.

2. Low Moisture Absorption:

FR4 Fiberglass Sheet has an extremely low moisture absorption rate of ≤ 0.5%. This property ensures stable performance even in humid environments, preventing swelling or performance degradation due to moisture absorption. Low moisture absorption is particularly important in electronic devices and electrical systems, as it prevents short circuits and insulation degradation, ensuring safety and reliability.

3. High Flexural Strength:

FR4 Fiberglass Sheet has a vertical layer flexural strength of ≥ 340 MPa, enabling it to withstand significant bending stress without breaking or deforming. In mechanical structures, this high-strength material can effectively support heavy loads, ensuring structural stability and safety. Whether used in electronic device housings or support structures for mechanical components, FR4 fiberglass sheet provides reliable protection.

4. High Compressive Strength:

FR4 fiberglass sheet has a perpendicular layer compressive strength of ≥ 350 MPa, meaning it can withstand significant pressure without crushing or deforming. In applications requiring heavy pressure, such as mechanical component supports and electronic device housings, this high-compressive-strength material ensures the structural integrity and stability of the equipment. Its excellent compressive resistance makes it an excellent choice for a variety of industrial applications.

5. High Impact Strength:

FR4 fiberglass sheet has a parallel layer impact strength (simple beam notch) of ≥ 37 kJ/m². This high impact strength allows it to withstand significant impact forces without breaking. In electronic devices and mechanical components, this high-impact material effectively prevents damage caused by accidental impact, ensuring long-term stable operation. Whether used for electronic device housings or mechanical component protection, FR4 fiberglass sheet provides reliable protection.

6. High Shear Strength:

FR4 fiberglass sheet boasts a parallel ply shear strength of ≥ 34 MPa. This high shear strength ensures stability under shear forces, preventing breakage or deformation. In mechanical structures and electronic devices, this high shear strength material effectively prevents structural damage caused by shear forces, ensuring device stability and safety. Its excellent shear resistance makes it highly effective in a variety of industrial applications.

7. High Tensile Strength:

FR4 fiberglass sheet boasts a tensile strength of ≥ 300 MPa, enabling it to withstand significant tensile forces without breaking. In mechanical components and electronic devices, this high tensile strength material effectively prevents damage caused by tensile forces, ensuring long-term stable operation. Whether used for electronic device housings or mechanical component support structures, FR4 fiberglass sheet provides reliable protection.

8. Excellent Insulation:

FR4 fiberglass sheet offers excellent insulation properties, effectively preventing current leakage and short circuits. This insulation quality is particularly important in electronic devices and electrical systems, ensuring their safety and reliability. Its stable chemical properties and high-density structure enable it to maintain excellent insulation performance in a wide range of environments, including those subject to high temperatures, humidity, and high mechanical stress.

FR4 Fiberglass Sheet Applications:

1. Electronic device enclosures:

FR4 fiberglass sheet is widely used in the manufacture of electronic device enclosures. Its high density, low water absorption, and high mechanical strength enable it to effectively protect internal components from environmental influences. Whether used in computers, communications equipment, or consumer electronics, FR4 fiberglass sheet provides reliable protection, ensuring long-term stable operation.

2. Printed circuit board substrates:

FR4 fiberglass sheet is one of the primary substrates for printed circuit boards (PCBs). Its excellent insulating properties and high mechanical strength enable it to withstand the weight and mechanical stress of electronic components while preventing current leakage and short circuits. In electronics manufacturing, FR4 fiberglass sheet is an indispensable material and is widely used in the manufacture of various types of printed circuit boards.

3. Mechanical Component Support:

FR4 fiberglass sheet is used to manufacture support structures for mechanical components. Its high flexural, compressive, and shear strengths enable it to withstand significant mechanical stress, ensuring the stability and safety of mechanical components. In mechanical manufacturing, FR4 fiberglass sheet is an ideal material for supporting and protecting various mechanical components.

4. Electrical Insulation Components:

FR4 fiberglass sheet is used to manufacture electrical insulation components. Its excellent insulating properties and high mechanical strength enable it to effectively prevent current leakage and short circuits, ensuring the safety and reliability of electrical systems. In electrical equipment, FR4 fiberglass sheet is a key material and is widely used in the manufacture of various electrical insulation components.

5. Aerospace Components:

FR4 fiberglass sheet is also widely used in the aerospace industry. Its high density, low water absorption, and high mechanical strength enable it to withstand mechanical stress and chemical corrosion in extreme environments. In aerospace components, FR4 fiberglass sheet provides reliable protection, ensuring long-term, stable operation of equipment.

6. Automotive Manufacturing:

FR4 fiberglass sheet is used in a variety of components in automotive manufacturing. Its high mechanical strength and excellent insulation properties enable it to withstand the mechanical and electrical stresses experienced during vehicle operation. FR4 fiberglass sheet is an ideal material for automotive electronic systems and mechanical components, and is widely used in the manufacture of various automotive parts.