GPO-3 Fiberglass Sheet for High Voltage Equipment

Please click the button below to contact us.

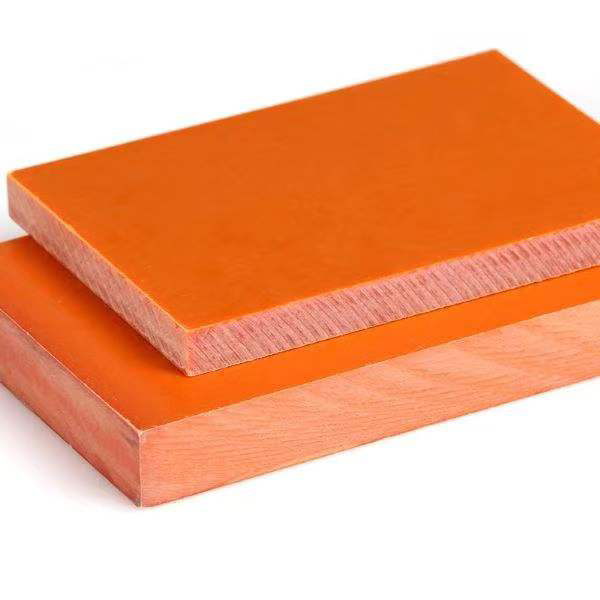

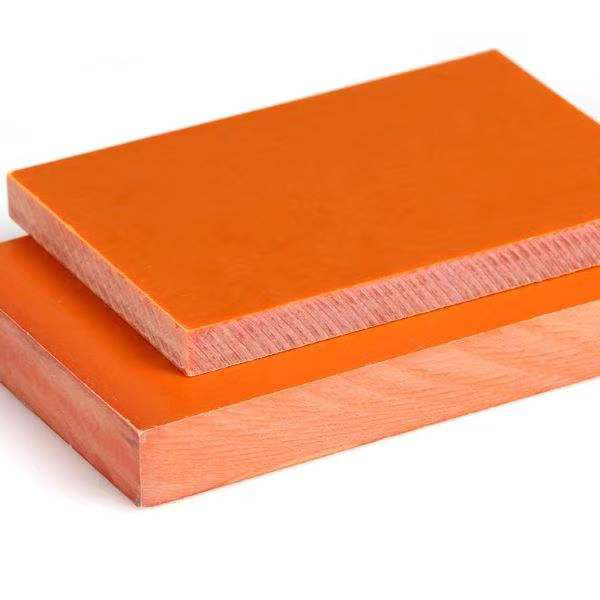

Introduction:GPO-3, a glass reinforced thermoset polyester sheet material, boasts strength, stiffness, and dimensional stability, making it ideal for electrical insulating applications. Additionally, its excellent electrical properties, including flame, arc, and track resistance, ensure reliable performance in demanding environments.

Product Description

GPO3 Fiberglass Sheet is a glass fiber-reinforced thermosetting polyester sheet material. Made using a specialized production process, it utilizes glass fiber as reinforcement and a polyester resin as a matrix. This material boasts high specific strength and modulus, providing excellent mechanical properties while maintaining a lightweight design. It also exhibits excellent chemical stability, resistance to acid and alkali corrosion, and is not susceptible to environmental factors. GPO3 Fiberglass Sheet's flexible molding process allows for customization and widespread application across a wide range of applications.

GPO3 Fiberglass Sheet Parameters:

| Physical Properties | |

| Specific gravity (ASTM D-792) | 1.81 |

| Tensile strength (ASTM D-638)Ps | 8000 |

| Compressive strength (ASTM D-695) Psi | 33100 |

| Flexural strength (ASTM D-790)Ps | 22100 |

| ZOD impact strength (notched) (ASTM D-256) ft.Ib/in | 8.9 |

| Water absorption (ASTM D-570)% | 0.4 |

| Electrical Properties | |

| Electrical strength (ASTM D-149)Vpm | 450 |

| Arc resistance (ASTM D-495) seconds. | 180 |

| Thermal Properties | |

| UL Topic 94 (0.094 inches and thicker) | V0 |

| UL temperature temperature index (UL746B) | |

| Electric | 130°℃ (266°F) |

| Mechanical | 160°℃ (320°F) |

| Thermal expansion coefficient (ASTM D-696)in/in/°CX10-5 | 2 |

| Thermal Conductivity (ASTM C-177) BTU/HR/Ft²/In/°F | 1.9 |

GPO3 Fiberglass Sheet Features:

1. High Strength:

GPO3 Fiberglass Sheet exhibits exceptional strength. Its tensile strength reaches 8,000 psi (ASTM D-638), allowing it to withstand significant tensile forces without breaking. This high strength makes it an excellent choice for electrical equipment and mechanical structures subject to heavy loads or stress, providing a solid foundation for stable operation.

2. High Rigidity:

This material boasts a compressive strength of 33,100 psi (ASTM D-695) and a flexural strength of 22,100 psi (ASTM D-790), demonstrating excellent rigidity. This high rigidity prevents deformation during use, ensuring it maintains a stable structural shape. This makes GPO3 Fiberglass Sheet particularly suitable for precision-critical components, such as insulation support components in high-voltage electrical equipment.

3. Excellent Dimensional Stability:

GPO3 Fiberglass Sheet has a coefficient of thermal expansion of only 2×10⁻⁵ in/in/°C (ASTM D-696), resulting in minimal dimensional change with temperature fluctuations. This ensures that it maintains stable dimensions across various ambient temperatures, preventing thermal expansion and contraction that could cause assembly issues or performance degradation, making it ideal for electrical and mechanical applications requiring stringent dimensional accuracy.

4. Excellent Electrical Properties:

GPO3 Fiberglass Sheet boasts an electrical strength of 450 Vpm (ASTM D-149), capable of withstanding high voltages without breakdown. Furthermore, its arc resistance time of up to 180 seconds (ASTM D-495) effectively prevents arc erosion in arc environments, ensuring the insulation performance and safe operation of electrical equipment, making it an ideal electrical insulation material.

5. Excellent Heat Resistance:

This material has passed UL 94 V0 testing (thicknesses 0.094 inches and above), demonstrating excellent flame retardancy. Its UL temperature index for electrical properties is 130°C (266°F), and its mechanical performance is 160°C (320°F). It maintains stable performance at elevated temperatures, making it suitable for electrical and mechanical applications in high-temperature environments.

6. Low Water Absorption:

GPO3 Fiberglass Sheet has a water absorption rate of only 0.4% (ASTM D-570), making it less susceptible to swelling or deformation in humid environments. This property ensures stable performance inside humid electrical equipment or in outdoor installations, extending service life and reducing maintenance costs.

7. High Impact Resistance:

With a notched charpy impact strength of 8.9 ft·lb/in (ASTM D-256), GPO3 Fiberglass Sheet exhibits excellent impact resistance. This high impact resistance allows GPO3 Fiberglass Sheet to withstand unexpected impacts without damage, enhancing equipment reliability in challenging environments.

GPO3 Fiberglass Sheet Application:

1. Insulation of High-Voltage Electrical Equipment:

GPO3 Fiberglass Sheet is widely used in high-voltage electrical equipment due to its excellent electrical insulation properties. For example, in high-voltage switchgear, it serves as an insulating barrier, effectively isolating components at different potentials, preventing arc short circuits and ensuring safe equipment operation. Its high electrical strength and arc resistance ensure excellent performance in high-voltage environments, ensuring equipment stability and reliability.

2. Transformer Insulation Components:

In transformer manufacturing, GPO3 Fiberglass Sheet can be used to make components such as insulating gaskets and insulating brackets. Its excellent dimensional stability and low water absorption ensure stable insulation performance during long-term operation, preventing degradation due to material deformation or water absorption, thereby extending the service life of the transformer.

3. Motor Insulation Structures:

GPO3 Fiberglass Sheet is suitable for motor insulation structures, such as stator slot insulation and rotor insulation. Its high strength and rigidity can withstand the mechanical stresses of motor operation while maintaining electrical insulation performance, preventing short circuits between motor windings, and improving motor efficiency and reliability.

4. Mechanical Component Manufacturing:

In addition to electrical applications, GPO3 fiberglass sheet can also be used in the manufacture of mechanical components. For example, in mechanical transmission systems, as support components for gearboxes, its high strength and rigidity can withstand heavy mechanical loads. Its corrosion resistance and low water absorption ensure it maintains good performance even in humid environments, reducing maintenance costs.

5. Electronic Equipment Housings:

GPO3 fiberglass sheet can be used in the manufacture of electronic equipment housings, such as high-frequency power supply housings. Its excellent electrical insulation and fire resistance protect internal electronic components from external interference and damage, while also preventing arcing and sparks within the equipment from causing fires, thereby improving the safety of electronic equipment.

6. Aerospace:

In the aerospace sector, GPO3 fiberglass sheet's lightweight and high-strength properties make it an ideal material choice. For example, in electrical insulation components for aircraft, its low water absorption and excellent dimensional stability adapt to the requirements of aircraft in diverse flight environments, reducing aircraft weight while ensuring the safe operation of electrical systems, thereby ensuring the high performance and reliability of aerospace equipment.

GPO3 Fiberglass Sheet FAQs:

What is GPO3 Fiberglass Sheet made of?

GPO3 Fiberglass Sheet is composed of fiberglass reinforcement materials combined with polyester resins.

What are the primary applications of GPO3 Fiberglass Sheet?

GPO3 Fiberglass Sheet is commonly used in electrical insulation applications such as switchgear, bus bar supports, and electrical enclosures due to its excellent electrical insulation properties and flame resistance.

How does GPO3 Fiberglass Sheet compare to other insulation materials?

GPO3 Fiberglass Sheet offers superior electrical insulation properties, high mechanical strength, and excellent flame resistance compared to many other insulation materials.

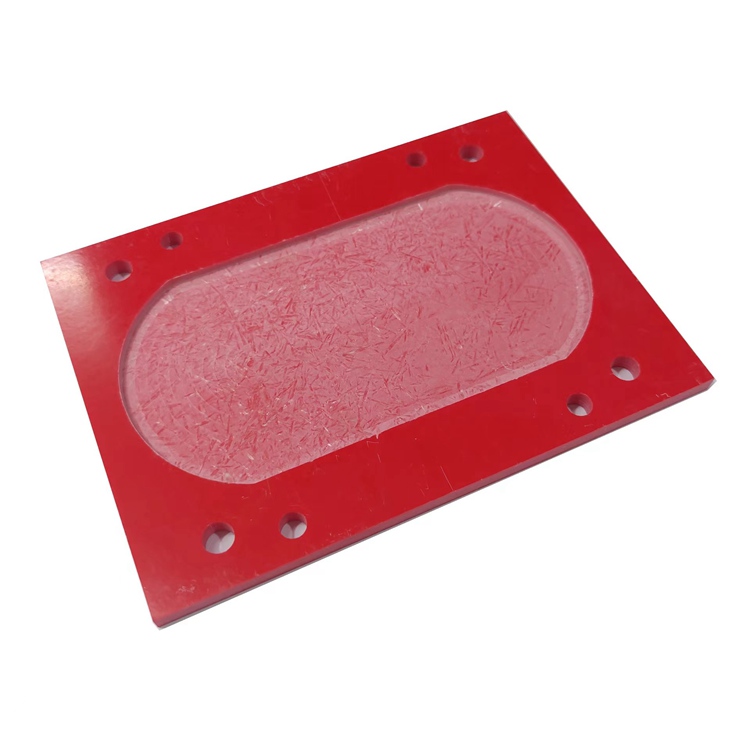

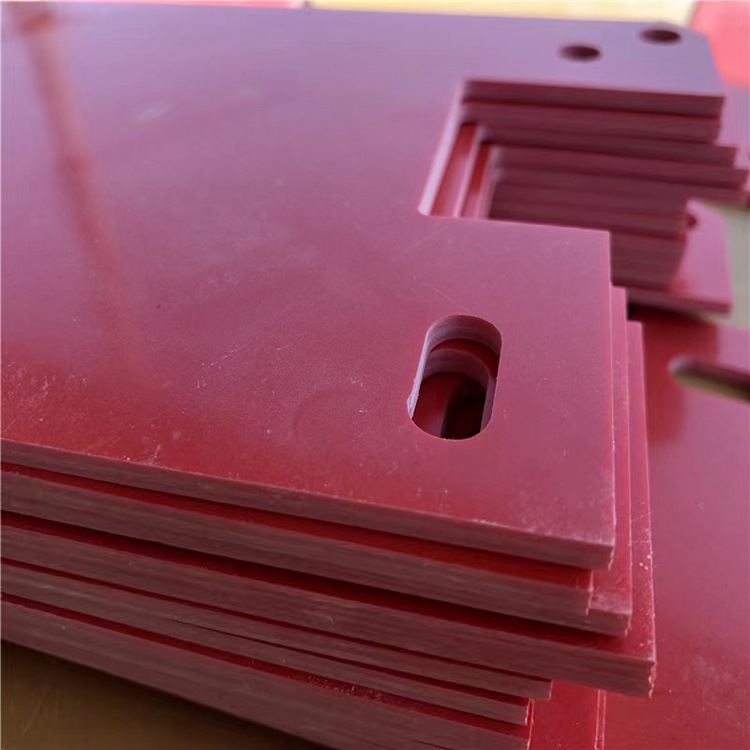

Can GPO3 Fiberglass Sheet be machined or fabricated?

Yes, GPO3 Fiberglass Sheet can be easily machined, drilled, sawed, and fabricated using standard tools and techniques.

What thicknesses are available for GPO3 Fiberglass Sheet?

GPO3 Fiberglass Sheet is available in various thicknesses ranging from 0.5mm to 50mm to suit different application requirements.

Does GPO3 Fiberglass Sheet require special handling or storage?

GPO3 Fiberglass Sheet should be stored in a dry environment away from direct sunlight and moisture to maintain its electrical and mechanical properties.

Can GPO3 Fiberglass Sheet be customized in terms of color or surface finish?

Yes, GPO3 Fiberglass Sheet can be customized in terms of color and surface finish to meet specific customer requirements.

What testing and quality control measures are in place for GPO3 Fiberglass Sheet?

GPO3 Fiberglass Sheet undergoes rigorous testing and quality control procedures to ensure compliance with industry standards and specifications.