Custom Sheet Molding Composite

Please click the button below to contact us.

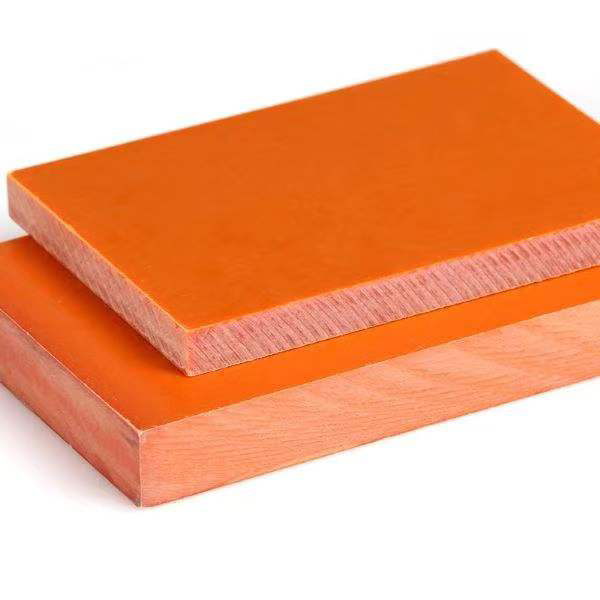

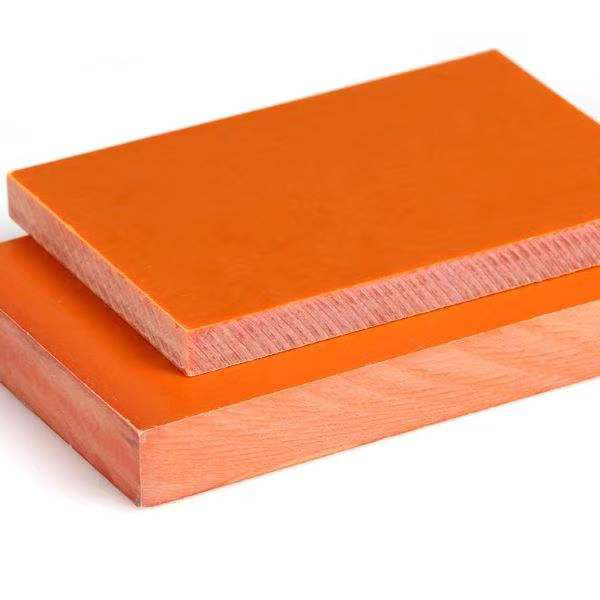

Introduction:Sheet Molding Compound is a sheet composite material made of glass fiber, unsaturated polyester resin, low shrinkage additives, fillers and additives. Through the compression molding process, it can be made into high-strength, lightweight and corrosion-resistant parts, which are widely used in automobiles, construction, electronics and other fields, replacing traditional metal or plastic materials.

Product Description

Sheet Molding Compound (SMC) is a composite material composed of a continuous fiber-reinforced thermoset resin matrix. Its primary components include long carbon or glass fibers dispersed in a resin bath of vinyl ester, polyester, or epoxy resin. This unique combination of materials imparts exceptional strength and durability to the final product. SMC is typically sold in roll form and can be cut into small pieces, called "slabs," to meet specific application requirements. During production, the fiber and resin are integrated by applying a resin paste evenly to a sheet, adding chopped fibers, and compressing the mixture between two layers of film. After storage to achieve the desired texture, the SMC is cured through a compression molding process, applying heat and pressure to create the finished product.

SMC Sheet Molding Compound Parameters:

| Indicator name | unit | Index value | ||

| 4341 SMC-1 | 4343 SMC-2 | 4331 SMC-3 | ||

| Density | g/cm3 | 1.75~1.95 | ||

| water absorbency | mg | ≤20 | ||

| Molding Shrinkage | % | ≤0.15 | ≤0.30 | |

| Heat distortion temperature (method A) | ℃ | ≥240 | ≥220 | |

| Impact strength (simple bracket, no notch) | KJ/m2 | 290 | 260 | 245 |

| Bending strength | MPa | 2170 | ≥150 | ≥135 |

| Insulation resistance: normal | Q | ≥1.0×1013 | 1.0×1012 | |

| After soaking in water for 24 hours | ≥1.0×1012 | |||

| Electrical strength (in 90°C transformer oil) | MV/m | ≥12.0 | ≥10.0 | |

| Dielectric loss factor (1MHz) | S0.015 | |||

| Relative dielectric constant (1MHz) | ≤4.8 | |||

| Arc resistant | S | 2180 | ≥150 | |

| Tracking resistance index (PTl) | V | 2600 | ||

| Flammability | level | FVO | ||

| Long term heat resistance temperature index | 155 | 130 | ||

Sheet Molding Composite Features:

1. High Strength:

Custom Sheet Molding Composite is renowned for its high strength, and its fiber-reinforced structure enables it to withstand extreme mechanical stress. With a density range of 1.75 to 1.95 g/cm³, this material combines exceptional strength with lightweighting. Compared to traditional metal materials, it offers higher strength at a reduced weight, making it widely used in the manufacture of components requiring high-strength support.

2. Low Water Absorption:

This product exhibits extremely low water absorption, absorbing only ≤20 mg of water. This property ensures that Custom Sheet Molding Composite maintains stable performance even in humid environments, preventing expansion or deformation due to water absorption. This makes it an ideal choice for outdoor equipment, marine applications, and other humid environments, effectively preventing material degradation.

3. Precision Molding:

Custom Sheet Molding Composite exhibits excellent dimensional stability during the molding process, with a mold shrinkage of ≤0.15 to 0.30. This means that during the high-temperature and high-pressure compression molding process, the material maintains precise dimensional accuracy, reducing processing errors and improving production efficiency and product quality. This property is particularly important for manufacturing products with complex shapes and high precision requirements.

4. High Thermal Stability:

With a heat deflection temperature (Method A) of ≥220-240°C, Custom Sheet Molding Composite maintains excellent mechanical properties and dimensional stability even in high-temperature environments. Whether used in automotive hoods, aerospace components, or other high-temperature applications, this material demonstrates excellent heat resistance, ensuring product reliability under extreme temperature conditions.

5. Lightweight:

With a density of only 1.75-1.95 g/cm³, Custom Sheet Molding Composite is significantly lighter than traditional metal materials. This lightweight feature not only helps reduce transportation costs but also improves product energy efficiency and performance. For example, in automotive manufacturing, the use of SMC can effectively reduce vehicle weight, thereby improving fuel efficiency and range.

6. Corrosion Resistance:

This product exhibits excellent corrosion resistance, resisting attack by a wide range of chemicals. Its resin matrix and fiber reinforcement structure ensure excellent stability in acidic and alkaline environments, preventing corrosion or degradation. This makes Custom Sheet Molding Composite an ideal material for corrosive environments such as chemical plants and wastewater treatment facilities.

Sheet Molding Composite Application:

1. Automotive Manufacturing:

In the automotive industry, Custom Sheet Molding Composite is widely used in body parts, hoods, bumpers, and other applications. Its high strength, lightweight, and corrosion resistance make it an ideal choice for lightweighting and enhancing vehicle performance. The use of SMC not only improves vehicle safety and fuel efficiency, but also reduces production costs.

2. Electrical Equipment:

Custom Sheet Molding Composite is suitable for electrical equipment housings, insulation components, and other applications. Its high thermal stability and low water absorption ensure safe operation in hot and humid environments. SMC's insulating properties and mechanical strength effectively protect internal components, preventing short circuits and damage.

3. Construction Industry:

In the construction industry, Custom Sheet Molding Composite is used to manufacture door and window frames, decorative panels, and other applications. Its corrosion resistance and lightweight properties make it an ideal choice for building materials, effectively improving the durability and aesthetics of buildings. SMC's processability allows it to be easily adapted to various architectural styles and design requirements.

4. Aerospace:

Custom Sheet Molding Composite (SMC) has important applications in the aerospace sector, such as aircraft interiors and wing components. Its high thermal stability and low water absorption enable it to maintain stable performance in extreme environments. SMC's lightweight properties help reduce aircraft weight, improving fuel efficiency and range.

5. Transportation:

In the transportation sector, Custom Sheet Molding Composite (SMC) is used in the manufacture of railway vehicle components and ship decks. Its corrosion resistance and high strength enable it to withstand the complex transportation environment and mechanical stresses. SMC's lightweight properties help improve the energy efficiency and load capacity of transportation vehicles.

6. Home Appliance Industry:

Custom Sheet Molding Composite is suitable for components such as home appliance housings and washing machine drums. Its corrosion resistance and high thermal stability ensure the safety and durability of home appliance products in daily use. SMC's processability makes it easy to create a variety of complex designs to meet consumer needs.

Sheet Molding Composite FAQs

Q1: Is SMC environmentally friendly?

A: RoHS-compliant, halogen-free, heavy metal-free, and recyclable at a rate of ≥90%.

Q2: Can the color and texture be customized?

A: Support RAL color card customization, minimum order quantity 500kg, delivery cycle 15-20 days.

Q3: Does the molding temperature affect the performance?

A: The molding temperature is 130℃-155℃, and the temperature fluctuation within ±5℃ has no effect on the performance.

Q4: How is the weather resistance?

A: After 5 years of outdoor use, the color difference ΔE≤3, and the tensile strength retention rate ≥85%.

Q5: How long is the service life?

A: More than 15 years for indoor use and 8-10 years for outdoor use (depending on environmental differences).