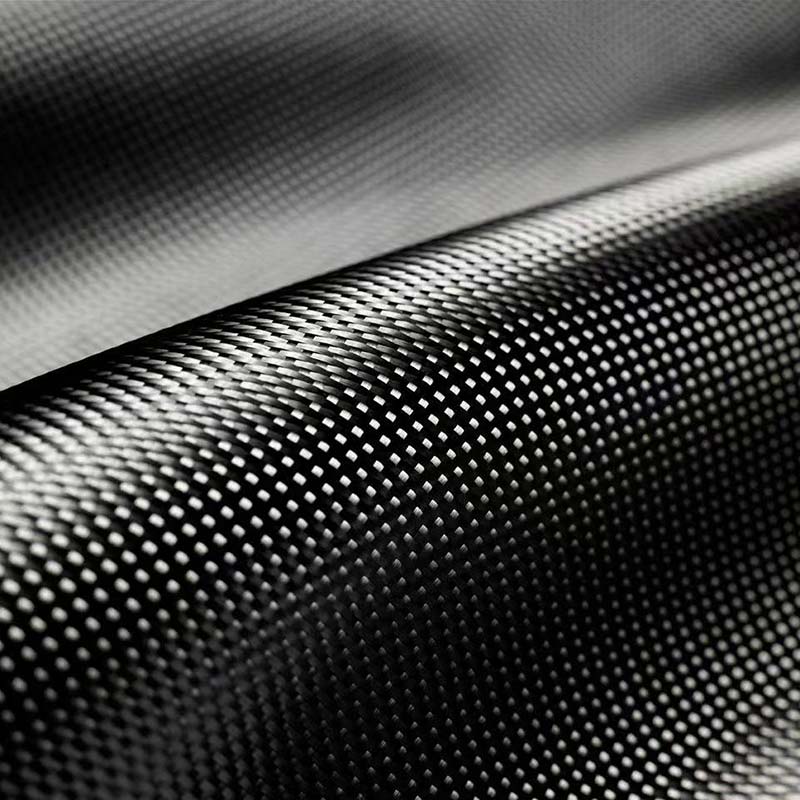

High-Performance Carbon Fiber Composite Sheet Material

In today's fast-paced industrial landscape, the demand for materials that combine strength, durability, and versatility has never been higher. The carbon fiber composite sheet has emerged as a leading solution, offering a unique blend of properties that make it highly sought after across various sectors. This article explores the six key advantages of carbon fiber composite sheets and their diverse applications.

Advantages of Carbon Fiber Composite Sheets

1. Lightweight and Strong

The carbon fiber composite sheet is renowned for its exceptional strength-to-weight ratio. With a density of only 1.75 - 1.85 g/cm³, it is significantly lighter than traditional metals like steel (density of 7.85 g/cm³). This lightweight characteristic is crucial in industries such as aerospace, where reducing weight can lead to substantial fuel savings and increased range. For example, replacing traditional metal parts with carbon fiber composite sheets can reduce the weight of aircraft by 20% - 30%, enhancing fuel efficiency and overall performance.

2. High Rigidity

Carbon fiber composite sheets exhibit remarkable rigidity, with an elastic modulus of up to 230 - 250 GPa. This high rigidity ensures that the material maintains its shape and dimensional stability under external forces, making it ideal for high-precision applications. Compared to aluminum alloy, carbon fiber composite sheets have 3-5 times the elastic modulus, reducing deformation and maintaining operational accuracy over extended periods. This is particularly important in the manufacturing of precision instruments and high-end machine tool components.

3. Corrosion Resistance

One of the standout features of carbon fiber composite sheets is their excellent resistance to corrosion. They can withstand prolonged exposure to harsh chemical environments, including acids, alkalis, and salts. For instance, these sheets remain stable even after long-term immersion in a 10% hydrochloric acid solution or a 20% sodium hydroxide solution. This durability makes them ideal for use in chemical processing equipment, marine applications, and offshore platforms, where corrosion resistance is critical.

4. Multi-Functional Versatility

Carbon fiber composite sheets offer more than just mechanical strength. They also possess a range of functional properties, such as good electrical conductivity (with a resistivity as low as 10⁻⁴ Ω·cm) and thermal conductivity (200 - 300 W/(m·K)). These properties make them suitable for applications in electromagnetic shielding and heat dissipation. Additionally, through specialized treatments, these sheets can be made fire-resistant, flame-retardant, and anti-static, further expanding their range of applications.

5. Customizability

Carbon fiber composite sheets can be tailored to meet specific requirements, offering flexibility in dimensions, surface finishes, and resin systems. This customizability ensures that the material can be optimized for various applications, providing the perfect balance of strength, weight, and functionality. Whether it is for aerospace components, automotive parts, or electronic housings, the ability to customize the material is a significant advantage.

6. Thermal Stability

Carbon fiber composite sheets maintain their structural integrity and mechanical properties across a wide range of operating temperatures, from sub-zero to high heat conditions. This thermal stability is crucial in applications where materials are exposed to extreme temperature fluctuations, such as in aerospace and automotive industries. This ensures that the material remains reliable and performs consistently, even under the most demanding conditions.

Applications of Carbon Fiber Composite Sheets

1. Aerospace Industry

In the aerospace sector, carbon fiber composite sheets are used extensively to manufacture aircraft wings, fuselage structural parts, and other critical components. Their lightweight and high-strength characteristics significantly reduce the overall weight of aircraft, leading to lower fuel consumption and improved flight efficiency. For example, modern commercial aircraft wings made from carbon fiber composite sheets are 25% lighter than traditional aluminum alloy wings, while maintaining the same level of strength and rigidity. This reduction in weight translates to a 15% increase in aircraft range.

2. Automotive Manufacturing

Carbon fiber composite sheets are increasingly being adopted in the automotive industry for manufacturing car body parts, engine hoods, and roofs. These sheets help reduce the weight of vehicles, improving fuel economy and overall performance. For instance, high-end sports cars that incorporate carbon fiber composite sheets in their body design can reduce the vehicle weight by up to 30%, resulting in a 0.5-second reduction in acceleration time from 0 to 100 kilometers per hour. Additionally, during collision tests, carbon fiber composite sheets effectively absorb and disperse impact energy, enhancing the safety of passengers.

3. High-End Sports Equipment

Carbon fiber composite sheets are ideal for manufacturing high-end sports equipment such as bicycle frames, fishing rods, and golf clubs. Bicycle frames made from these sheets are significantly lighter and stronger than traditional metal frames, reducing weight by 40% - 50% while maintaining excellent anti-fatigue performance. This makes them perfect for long-term use, providing riders with better handling and comfort. Similarly, fishing rods and golf clubs made from carbon fiber composite sheets benefit from their high rigidity and lightweight, enhancing the performance of the equipment.

4. Electronic Equipment Manufacturing

In the electronics industry, carbon fiber composite sheets are used to produce housings and heat dissipation components for electronic products. Their good electrical conductivity and thermal conductivity make them suitable for electromagnetic shielding and heat dissipation applications. For instance, heat sinks made from carbon fiber composite sheets in high-performance computers can efficiently dissipate heat generated by the chip, ensuring stable operation under high load conditions. The lightweight nature of these sheets also contributes to making electronic devices more portable.

5. Medical Equipment Field

Carbon fiber composite sheets play a crucial role in the medical equipment industry, used in the manufacturing of surgical instruments and medical equipment housings. Their biocompatibility and corrosion resistance make them suitable for use in medical devices that come into contact with the human body. For example, surgical instruments made from carbon fiber composite sheets do not cause adverse reactions in the human body, ensuring the smooth progress of surgical procedures. In the case of medical equipment housings, these sheets provide protection against external factors that could interfere with or damage the precision components inside.

The carbon fiber composite sheet is a versatile and high-performance material that offers a range of advantages, including superior strength-to-weight ratio, exceptional rigidity, outstanding corrosion resistance, multi-functional versatility, customizability, and thermal stability. These features make it an ideal choice for a wide array of applications across industries such as aerospace, automotive, sports equipment, electronics, and medical equipment. As technology continues to advance, the potential for further innovation and application expansion of carbon fiber composite sheets remains vast, promising to drive progress in various fields and contribute to the development of next-generation products.

Previous: What Is Phenolic Resin?